The process of making a guard

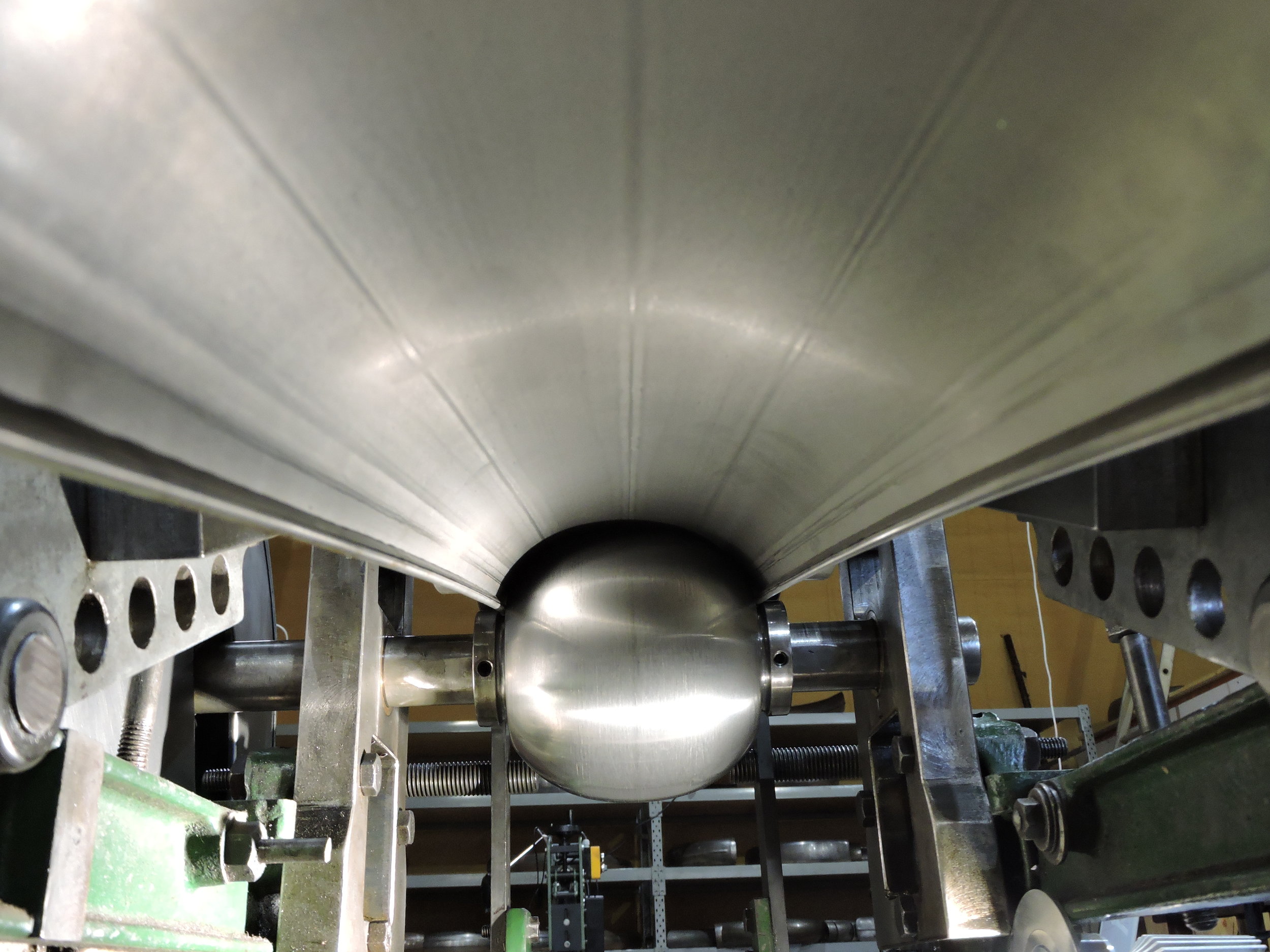

All the mudguards start as a flat piece of sheet metal and are firstly prepared using a bender and bead roller. Two passes through the bead roller produce a rolled edge and the bender just gives the guard a shape that will allow it to enter the rollers for the first time to set the gutter shape, any fold lines are rolled out in the rolling process leaving no creases at all. A specific CNC machined set of form rollers is then used for each profile of guard.

Most British guards have a rolled edge while American fenders generally have flat edges. There are some exceptions to this like the Indian motorcycles from the teens and early 1920’s which used rolled edges.

With the profile shape set we proceed to introduce the curve to the guard by applying pressure and with many gentle passes through the rollers the shape begins to form. The minimum number of passes is around 40 for the smaller guards to produce the required radius with up to 80 passes for the big 1920s Ace fenders.

Part way through the guard takes on a nice smooth shine that makes a great surface for paint or plating if required.

We can roll a guard or fender to any radius that is required. We will need to know quite a few measurements of the width, depth, length and radius and any other things like side pressings, number plate pressings, rolled noses or tails, duck-billing, 2-piece joins etc. We leave the hole drilling and mounting to the restorer due to the many variations of stays and bracket setup.

Over 240 valance templates are available for a large range of Veteran and Vintage motorcycles. These range from a small half valance on a veteran guard to full length valances with bottom skirts or complex multi piece valances with belt rim and brake rim covers.

We have templates for a number of mounting brackets and stays but normally only make these if they are an important element of the guard that isn't easily added later. We are constantly adding to the range of templates as we get hold of an original sample and make new patterns to reproduce them.

Our press tool range is extensive and growing, allowing us to make very complex finished guards and fenders.

We have many different rollers and dies to produce 100s of different guards. We’ve made guards for motorcycles, sidecars, hot rods, vintage cars, caravans, custom trucks and even machinery. We also supply blank uncut guards or fenders for you to modify to your own requirements.

FREQUENTLY ASKED QUESTIONS (FAQs)

Q - What type of steel is used and where does it come from?

A - We use a cold rolled BlueScope Steel product CA3SN-G which is used for making car panels. It is ductile and malleable of moderate strength – which means it reasonably formable and can tolerate repeated working. The raw Iron Ore is mined from the Pilbara in Western Australia, smelted and hot rolled at Port Kembla in NSW and finally cold rolled and annealed at the Westernport site in Victoria before being sent back to us in WA.

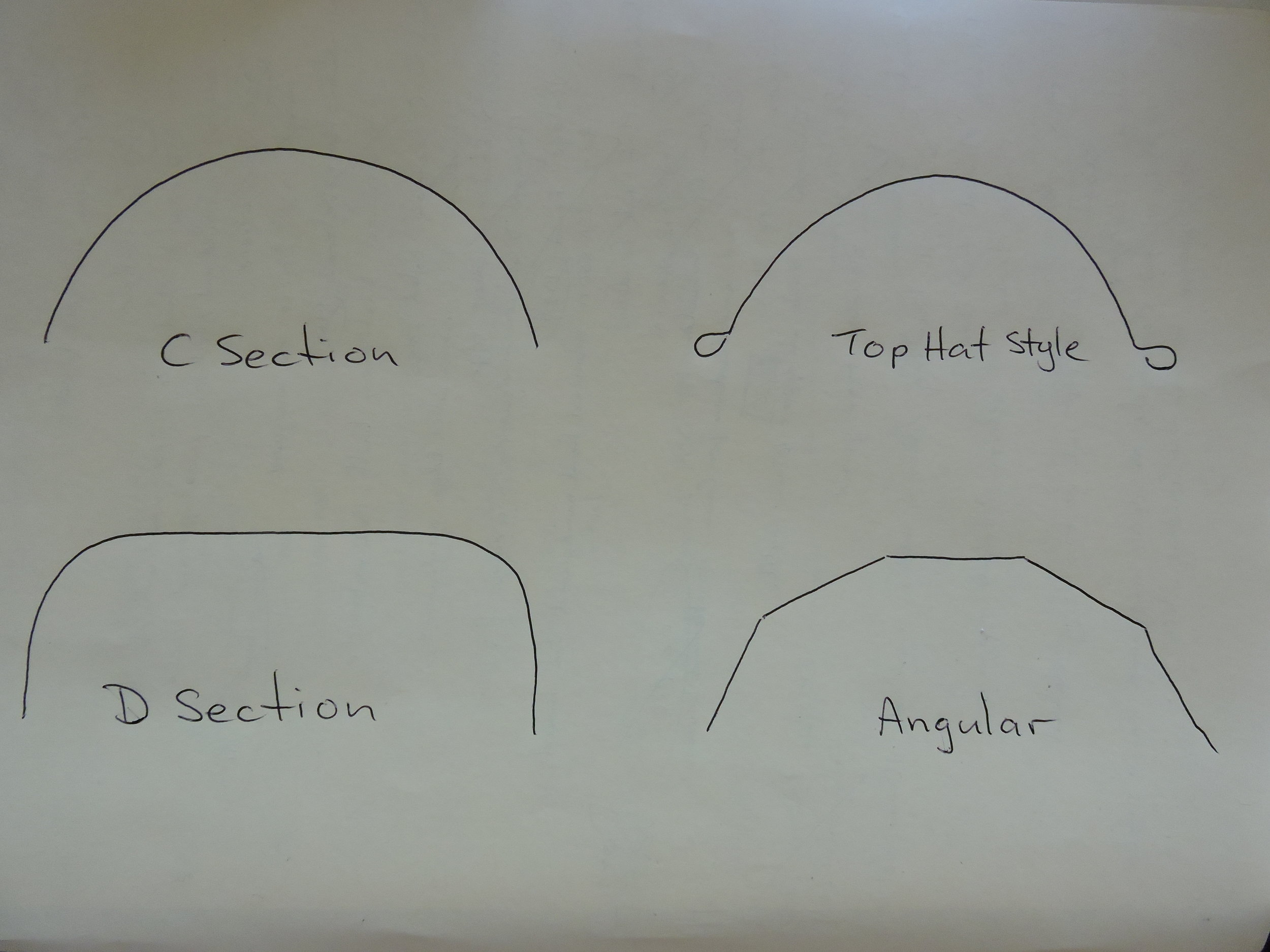

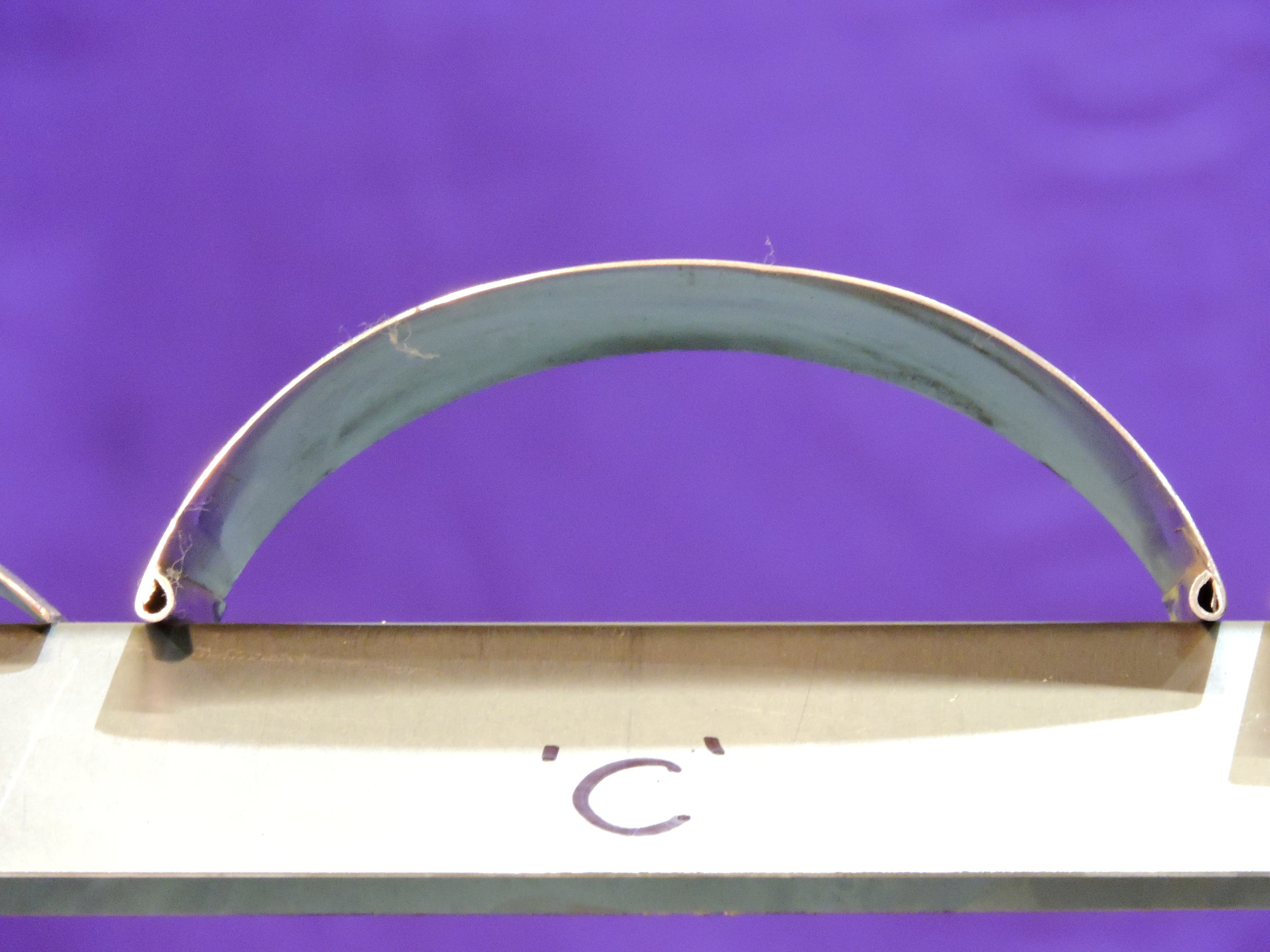

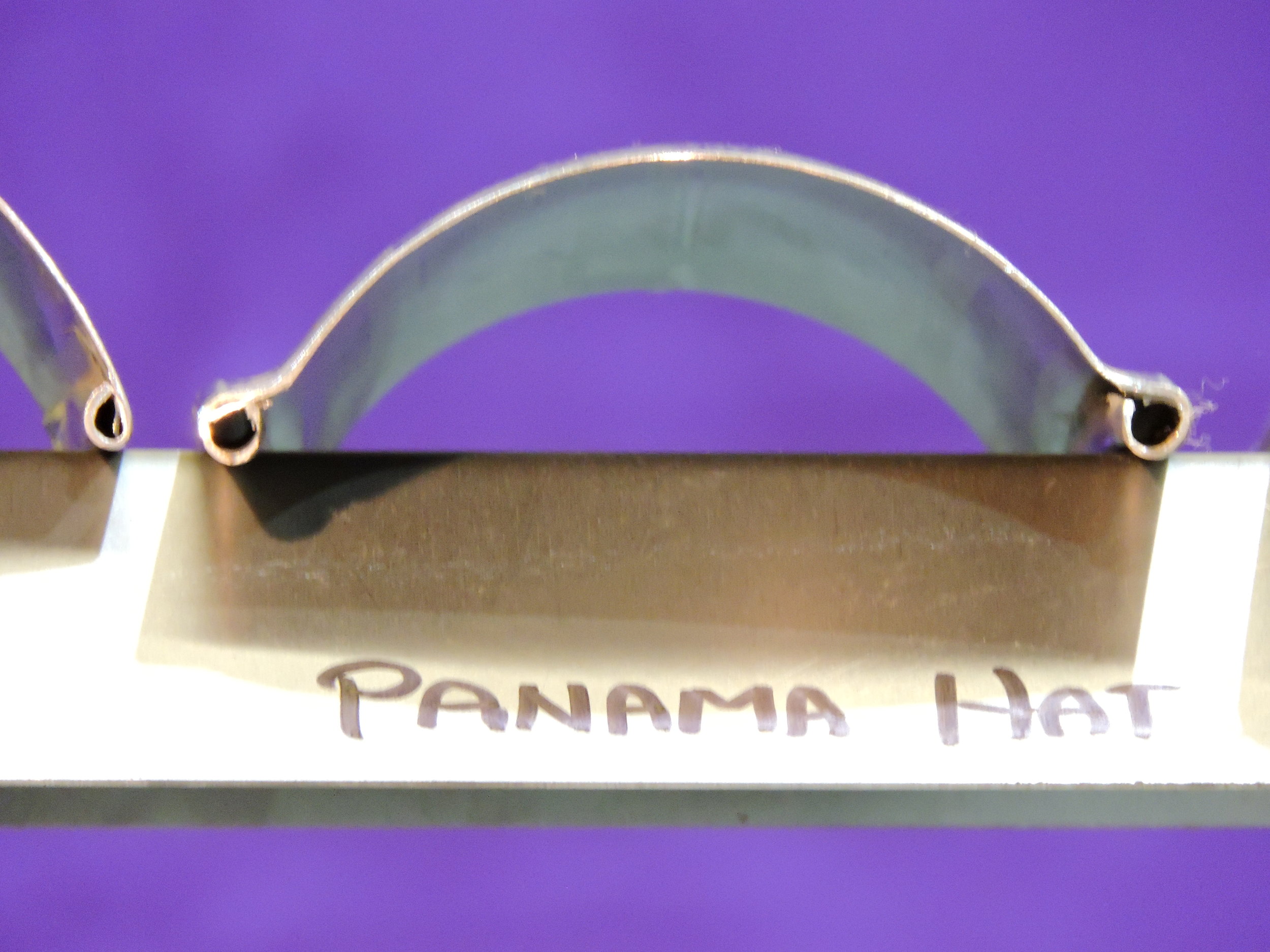

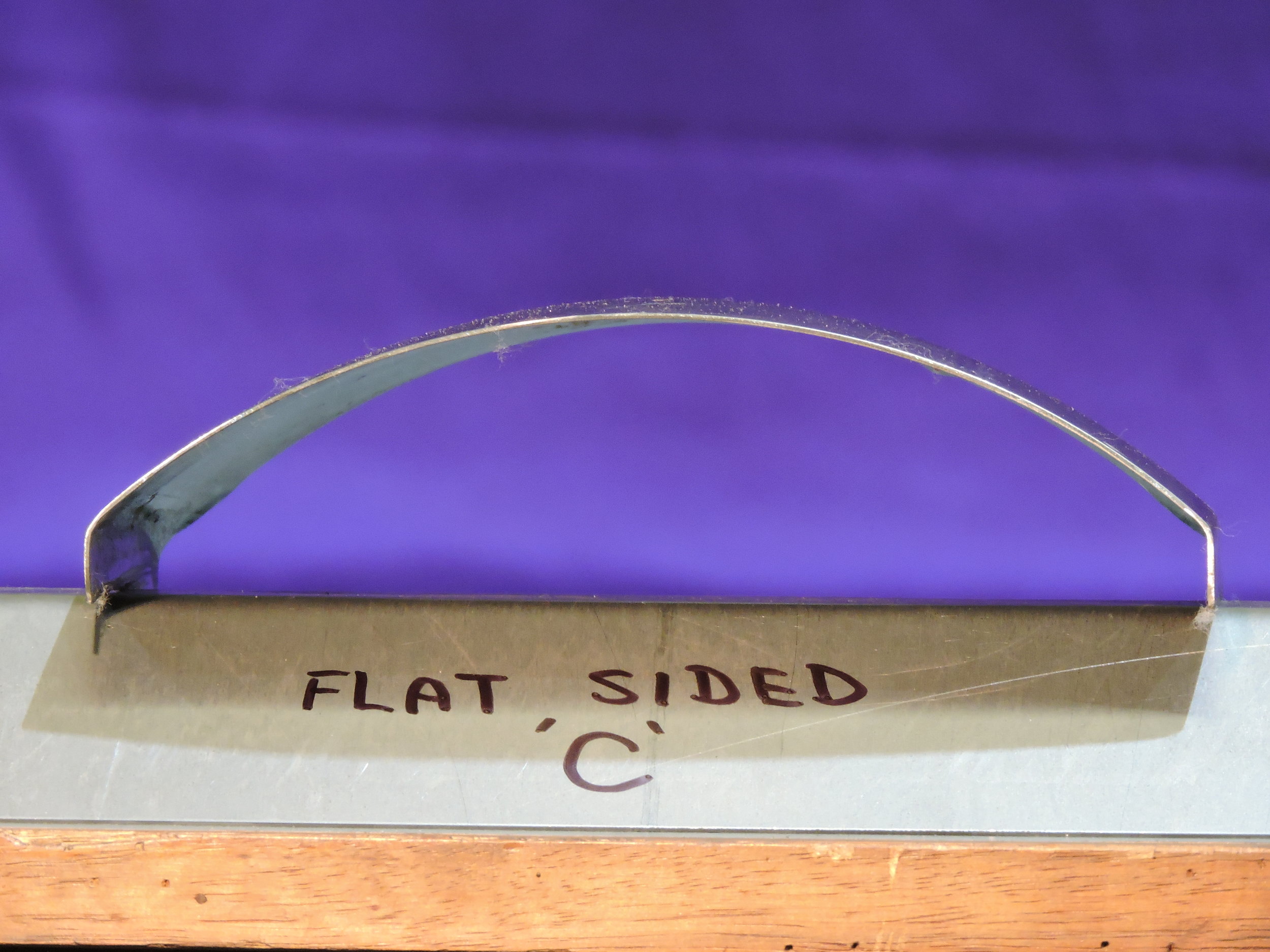

Q - What does 'C' Section or 'D' Section mean?

A - This is a description of the cross section or profile of the guard. The photos below show a few examples but there is no strict definition so use these as a guide to help us all speak the same language. Generally a 'C' Section guard has a continuous curve from one side to the other whereas a 'D' Section has flattish sides and top. A Panama Hat style has the rolled edges protruding beyond the sides of the guard.

Q - Why do some guards have rolled edges and some don't?

A - Most British, European, Japanese and Australian manufacturers used rolled edges to add stiffness and strength to the guards. It also provided a safe edge for handling and meant that lighter gauge steel could be used, thus keeping weight down. Most American manufacturers opted instead for a heavier gauge steel to maintain stiffness and have plain cut edges on their fenders. Our rollers are made to reproduce the original whichever way they were made.

Q - Can I give you the tyre size on my bike so you can make a guard for it based on that size?

A - We need more information than the tyre size. As it is moved further away from the top of the tyre, the guard radius increases. A good starting point is to compare the gap or overlap of the inside edge of the guard with the outside (tread) of the tyre. If you don't have an old guard, we will need measurements to frame mounting points.

Q - What are the narrowest and the widest guards you make?

A - The narrowest we make is 66mm or 2.6 inches. The widest is 186 mm or 7.37 inches. This is because they are rolled on form rollers which are machined to the exact profile of the guard. For many of our profiles we have the flexibility to narrow or widen the resultant profile by up to 10%.

Q - Can you make a new profile of a guard if it’s not in your sets already?

A - Yes, we can but we would need to be confident of a reasonable number of sales to commission the production of new rollers and the R&D needed to make the first sets. We have most recently invested in new rollers for a 6 1/4” (159mm wide) C section rolled edge mudguard profile. We are also happy to discuss a shared investment if you have a custom or very rare shape in mind.

Q - Do you do bulk orders?

A - Yes, we do bulk orders and offer discounts starting at 10% on orders of 6 or more of the same guard.

Q - How quickly can you make my guard?

A - We have a number of blank guards in stock. If we have one in stock at the radius you require then it could be made within a week. If we have to do a run to make the required profile, then it will be placed in the queue. A steady inflow of orders has seen our order queue for non-stock items grow to 20 working weeks.

Q - Why the need for a 50% deposit?

A - Each guard is custom made to your requirements and we may never get another order for the same thing. Because there are literally hundreds of different types we can’t afford to have them all on the shelf in the hope that we might sell them. A 50% deposit means you are a serious buyer so we have to get serious about making the perfect guard for you.

Q - Do you charge postage?

A - Yes. The cost of the custom boxing and postage charges are added to the price. The custom boxing and packaging is approx $30 and weighs normally 1.5 to 2kg for an average pair of guards. Here is a LINK to the Australia Post international calculator. Just enter your weight estimate and destination country.

For Australian customers, here is a link to the Australia Post domestic calculator table. Once again add approx $30 and 1.8kg.

Q - Where is your workshop? Can I visit?

A - Our workshop is in Donnybrook, Western Australia about 2 hours South of Perth. Visits can be arranged if you contact us preferably by email. We have many groups visit and know now that you should plan for an hour because there will be many questions.

Q - Can you make car fenders?

A - There are some open wheelers and vintage sports cars (see the Alvis race-car guards in our mudguards section) that use cycle guards we can make. We also make custom guards for hot-rods and other vehicles. These are all based on cycle guard profiles that have a side to side symmetry. We can also custom make spare wheel covers.

Q - Can you make my guards in Aluminium or Stainless Steel?

A - Yes, most can be rolled in aluminium (or copper), but please talk with us about your requirements. We no longer have access to a suitable grade of Stainless Steel for rolling as worldwide demand for this material is minimal.

Q - Do you make mudguard stays and brackets?

A - There are so many variations on stays that we can't possibly try to match so we are trying to stay with our speciality for now and just make mudguards and fenders. There are some we do make, but in general, it is not worth making here what your local shop can do. With brackets it has become necessary to make some because they are an integral part of the guard, but we don’t have a full range of patterns.

Q - Do you send guards or fenders overseas?

A - Yes, we can send our guards anywhere in the world that the postal service or courier is available.

Q - Do you charge GST / VAT? (Goods & Services Tax / Value-Added Tax)

A - Australian local sales include GST. GST/VAT is not collected on guards that are exported out of Australia. In most cases this is collected by your government at the point of import.

Q - Can I insure my guards against post office loss?

A - Yes you can, or we can insure them through the Australian Post Office system if required. Please ask. The cost is approx 4% of the value insured.

Q - Do I need to send you my rusty sample guard so you can make a new one?

A - There will be occasions where the best option is to have your sample guard on the bench in front of us, however, in most cases we will already have drawings or templates to work with and may only need some measurements or photos of your sample or your bike. We can advise you on how to package your guard if necessary to minimise damage and postage costs.